Solvent boils/popping

Definition

Blister-like surface defects due to solvents trapped in the paint film.

Causes

- Excessive film build

- Hardener and/or reducer too fast

- Flash-off time between spraycoats too short

- Flash-off time before baking or infra-red drying too long

- The panel temperature becomes too high when the distance between IR lamps and painted object is too small

- Flash-off time between spraycoats too short for wet-on-wet process

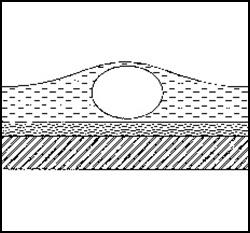

Cross-section through a paint-film with Solvent-Boil, 200 x magnification

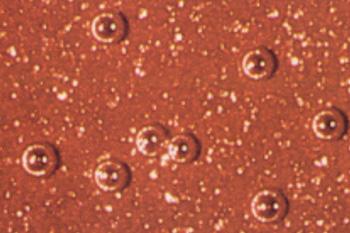

Solvent-Boil in Clear Lacquer coat, 100 x magnification

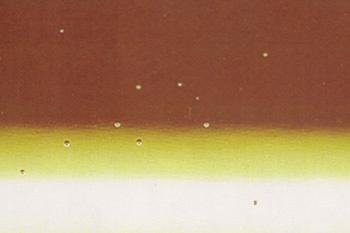

Solvent-Boil visible on a paint surface

HOW TO AVOID

- Keep to recommended film builds.

- Use hardener and reducer suitable for the ambient temperature (see temperature table).

- Keep to recommended intermediate flash-off times.

- When using Glasurit products, no flash-off time is required before baking.

- Keep to recommended distances and intensities when drying with infrared.

- Keep to recommended film builds and flash-off times between coats.

REPAIR

For surface defects caused by solvent boils, sand the paint system down to a “sound” substrate. Refinish using the recommended undercoats and/or topcoats. If solvent boils are not completely removed by sanding, pinholes will appear once the next coats have been applied (see entry on “Pinholing”).

A brand of

A brand of