Faults in painting plastics - Cracking

Definition

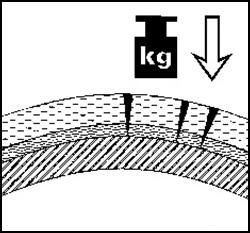

Break or crack lines in the paint finish after mechanical stress. In severe cases the plastic may also crack. This problem is normally associated with soft flexible parts (e.g., PU rear spoilers).

Causes

- Insufficient use or no use of Glasurit 522-111 Softface Additive

- Total film build too high

2 x magnification

HOW TO AVOID

- The amount of Glasurit 522-111 Softface Additive added to the paint depends on the degree of flexibility required and whether the plastic is rigid (hard) or soft (flexible). Soft plastics are made of PU foam (e.g. rear spoilers) and can be easily indented with the thumb. All other plastics are rigid (hard). In principle, the filler, topcoat and clearcoat layers must be plasticized. Softface Additive is not used with basecoats.

- Hard/rigid plastics: Mix the topcoat/clearcoat 4:1 by volume with 522-111 before adding the hardener and reducer. VOC-compliant topcoats/clearcoats do not require the use of 522-111.

- Soft/flexible plastics: Mix the topcoat/clearcoat 2:1 by volume with 522-111 before adding the hardener and reducer. Mix VOC-compliant topcoats/clearcoats 4:1 with 522-111 before adding the hardener and reducer. Note: First add 522-111, and then add hardener in the recommended mixing ratio.

- Keep to recommended film thicknesses.

REPAIR

If possible, remove the paint layers mechanically and then refinish according to Refinishing System S 3. Do not use a paint stripper as this might damage the plastic!

A brand of

A brand of