Paint system

Layer for layer: The structure of automotive finishes

Every automotive finish is an attractive eye-catcher and important protective coat in one. The demands the finish is subjected to are high and can be met only by a multilayer system.

How a finish is prepared

- Substrate

When a vehicle is repainted or the finish repaired, the first step involves removing paint residues and rust and thoroughly cleaning and degreasing the body. The substrate must be free of any dirt particles, tar, oil or wax. The body is then sanded. In addition to removing paint residues and rust, the sanding process is also designed to achieve optimal adhesion to the substrate. It is also necessary for leveling out any uneven areas. The choice of the sanding paper's grit size depends on the subsequent coat to be applied.

- (Welding primer)

If extensive, time-consuming welding operations are required, the use of a primer approved for welding will be necessary. This primer can be safely used for welding work with respect to the gases and fumes generated. It also prevents the surrounding coat from being burned off and keeps dangerous splatter from being produced during welding. After the welding operation and before the body filling work is done, this coat should be removed. -

Body filler

Uneven areas can be filled in and evened out with a body filler. This can be done in a single working step or in several working steps in the form of fine and/or coarse body filling. The body filler is then sanded. - Primer filler

The primer filler makes the individual layers adhere to each other, thus ensuring the durability of the paint system. It also evens out minor irregularities and ensures that the substrate will be uniformly smooth and protect the coating against stone chipping. The primer filler also produces the high-quality appearance of the finish. -

Topcoat/basecoat

The topcoat is the layer in the paint system that catches the observer's eye. It provides color, gloss and special effects. It may be a direct-gloss system (solid colors) or a basecoat/clearcoat system. Furthermore, to bring about the right color, a topcoat may also consist of several color coats. In addition to its visual characteristics, this layer is also designed to provide protection against external influences such as weather, the environment and scratches. -

Clearcoat

As the last coat, a clearcoat layer protects the entire finish from external influences such as wind, weather or brushes at the car wash. The clearcoat also lends the finish the desired gloss level – from high-gloss to mat.

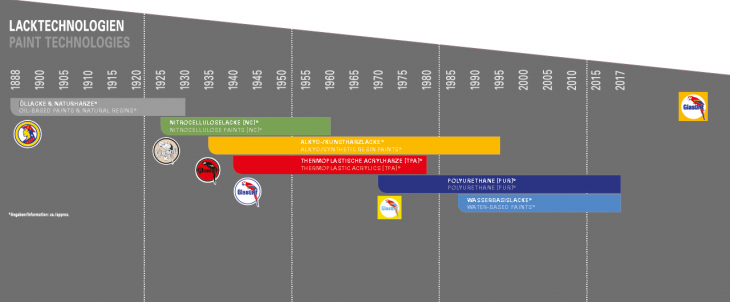

The composition of paints

Synthetic resins, also referred to as binders, serve as the basis of modern paint products. They determine the physical properties of the paint, such as drying, film formation, gloss, adhesion and resistance to external influences.

For all paint products such as primer fillers or topcoats, the synthetic resins with the desired properties are mixed together and then combined with other paint ingredients.

In order for this mixture to become a resistant coating, the paint must be applied and heated. The heat in the spray booth ensures that the synthetic resins are permanently combined and form a net covering the body.

And what happens when the finish has been damaged? Find out more about the topic of Paintwork repair.

Discover our automotive refinish products as well as our paints for trucks and our paints for classic cars.

A brand of

A brand of