Cratering

Definition

Round recesses with a diameter from 0.5 to 3 mm. The appearance ranges from very flat depressions in the final layer of paintwork to serious wetting problems that go all the way down to the substrate. Craters that have been overcoated after inadequate refinishing can become visible again as flat recessions.

Causes

Mainly: Oil, grease, wax and silicone residue (e.g., polishes containing silicone):

- Humans – impregnated working clothes, rubber gloves, skin and hair care products

- Spraybooth – lubricants from moving parts, mold release agents from plastic add-on parts, hoses and sealing compounds, poorly cleaned oil and waste water separators, dirty filters in ceiling and floor

- Paint materials – incorrect use of additives (anti-silicone additive), unsuitable reducers (hardeners) from other suppliers, impurities in the coating due to deficiencies in transport and storage

- Workpiece – residues from mold release agents on plastic parts, residual drawing agents and lubricants, soldering pastes, bitumen and oil from insulating mats

- Painting process additives – mold release agents from new sponge cloths, unsuitable cleaning agents and cloths, unsuitable sanding media (scouring cleaners), adhesive from adhesive tapes

- Environment – aspiration of contaminated air (polishing agent, silicone spray, fine dust, etc.) from other parts of the bodyshop, seals and insulating materials from the building

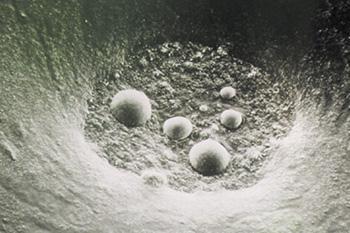

50 x magnification

100 x magnification

50 x magnification

HOW TO AVOID

Items 1-6 list possible sources of cratering. Consequently, various preventive measures to eliminate cratering can be established. As a basic principle, we recommend to use only silicone-free products in paintshops and to thoroughly clean the substrate.

REPAIR

Sand down the paint system to a “sound” surface. Refinish using the recommended undercoats and topcoats.

A brand of

A brand of