Expert Knowledge

Your reliable business partner

From first-class paints to comprehensive refinishing solutions, Glasurit is the leading paint partner of choice for bodyshops across the world. We’re committed to your success.

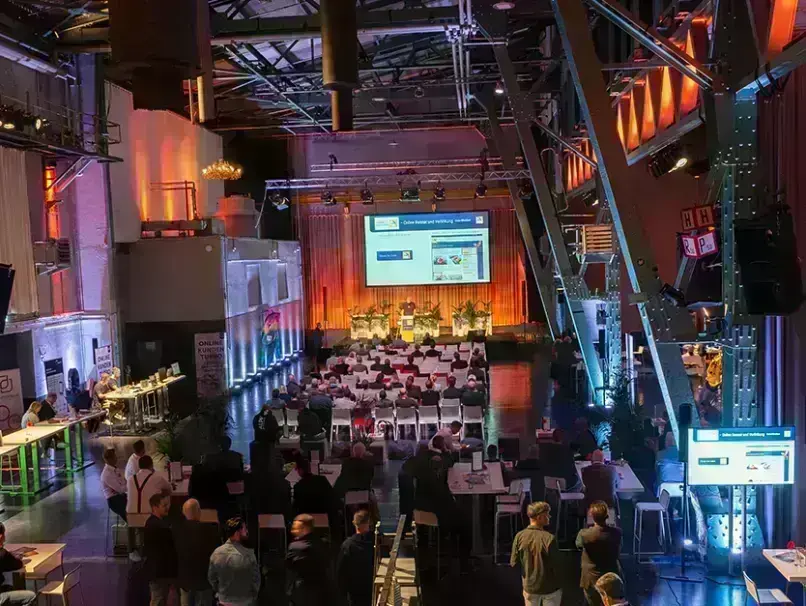

Trending in expert knowledge

Our consultancy services

What we can do together

Give your business the power to fly

Meet a digital platform designed to drive your business success. Quickly access solutions designed for color, learning, business management, support and trusted partner solutions. Designed to help you succeed in the digital age. The power of one platform is here.

Our expert technical support

Learn and improve with our help and guidance

Sustainable solutions

At Glasurit, we believe in helping you achieve long-term and sustainable body shop success. Become a leader in the collision industry and bolster your sustainability contributions and position your business with Glasurit #EcoEffective solutions.